In the realm of heavy industry, the integration of Artificial Intelligence (AI) is increasingly becoming a focal point for businesses seeking to enhance their operational efficiency and productivity. Understanding the role of AI in industrial settings and recognizing its potential impact on heavy industry is essential for organizations looking to stay ahead in the digital transformation landscape.

Will AI Save Heavy Industry?

Yes, AI has the potential to save heavy industry by enhancing efficiency, reducing costs, and improving safety. Through advanced data analytics, AI can optimize production processes, streamline supply chains, and predict equipment failures before they occur. This predictive maintenance can minimize downtime and extend the life of machinery, leading to significant savings. Additionally, AI-powered automation can improve precision in tasks, reduce human error, and allow for better resource management, ultimately driving higher productivity levels in heavy industry.

However, the successful implementation of AI in heavy industry depends on several factors, including the readiness of existing infrastructure, workforce training, and the ability to integrate new technologies with traditional systems. If companies do not adapt to these changes, they may face challenges in fully realizing AI's benefits. Therefore, while AI holds promise for transforming heavy industry, its effectiveness will vary based on how well organizations navigate the transition.

Introduction to AI in Industrial Settings

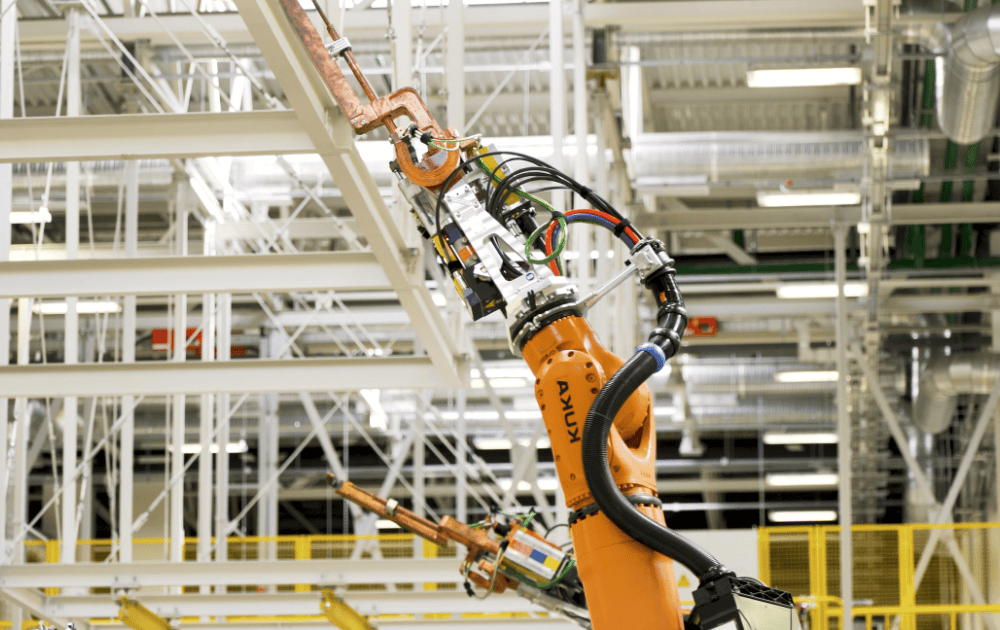

AI in industrial settings refers to the application of advanced algorithms and machine learning techniques to automate and optimize various processes within heavy industry sectors such as manufacturing, construction, and energy. By leveraging AI technologies, businesses can analyze large datasets, detect patterns, and make data-driven decisions in real-time, leading to improved operational performance and cost savings.

AI solutions in heavy industry encompass a wide range of applications, including predictive maintenance, process optimization, and safety enhancements. These applications are designed to streamline operations, minimize downtime, and enhance overall productivity, ultimately driving business growth and competitiveness in the market.

Potential Impact of AI on Heavy Industry

The potential impact of AI on heavy industry is profound, with the technology poised to revolutionize traditional operational practices and unlock new opportunities for growth and innovation. By harnessing the power of AI-driven analytics and automation, businesses in the heavy industry sector can achieve the following benefits:

| Potential Impact of AI on Heavy Industry |

| Increased Operational Efficiency |

| Enhanced Predictive Maintenance |

| Improved Safety Protocols |

| Optimal Resource Utilization |

| Cost Reduction through Process Optimization |

As heavy industry continues to evolve in the digital age, the adoption of AI technologies is crucial for organizations looking to navigate change, drive sustainable growth, and remain competitive in an increasingly dynamic market landscape. By embracing AI solutions tailored to the specific needs of heavy industry sectors, businesses can position themselves for success and pave the way for a more efficient and resilient future.

Applications of AI in Heavy Industry

In the realm of heavy industry, Artificial Intelligence (AI) is making significant strides in enhancing operational efficiency and productivity. The key applications of AI in heavy industry include predictive maintenance, process optimization, and safety enhancements. This discussion highlights how these technologies can improve efficiency and reduce risks in various industrial settings.

Predictive Maintenance

Predictive maintenance is a critical application of AI in heavy industry, revolutionizing traditional maintenance practices. By leveraging AI algorithms and machine learning, companies can predict equipment failures before they occur, allowing for proactive maintenance interventions.

| Benefits of Predictive Maintenance |

| Reduces downtime and unplanned outages |

| Increases equipment lifespan |

| Optimizes maintenance schedules |

| Improves overall operational efficiency |

Implementing predictive maintenance systems powered by AI enables heavy industry businesses to move away from reactive maintenance approaches towards a more cost-effective and reliable predictive maintenance strategy.

Process Optimization

AI plays a pivotal role in optimizing processes within heavy industry operations. By analyzing vast amounts of data in real-time, AI systems can identify inefficiencies, streamline workflows, and enhance overall production processes.

| Benefits of Process Optimization with AI |

| Increases production efficiency |

| Reduces waste and resource consumption |

| Enhances product quality |

| Enables real-time monitoring and adjustments |

Through advanced analytics and AI-driven insights, heavy industry organizations can achieve higher levels of operational excellence, leading to improved performance and competitiveness in the market.

Safety Enhancements

Safety is paramount in heavy industry, and AI technologies are being harnessed to enhance workplace safety standards. AI-powered systems can detect potential safety hazards, monitor employee activities, and provide real-time alerts in hazardous situations.

| Safety Enhancements Enabled by AI |

| Early detection of safety risks |

| Implementation of preventive measures |

| Continuous monitoring of safety protocols |

| Prompt response to emergencies |

Integrating AI-driven safety solutions helps heavy industry businesses create safer work environments, reduce accidents, and protect their workforce. These technologies monitor conditions, identify hazards, and enable proactive safety measures, enhancing both employee well-being and operational efficiency.

The applications of AI in heavy industry, including predictive maintenance, process optimization, and safety enhancements, are paving the way for a more efficient, productive, and secure industrial landscape. Embracing AI technologies in these key areas can drive substantial improvements in operational performance and establish a foundation for long-term success in the heavy industry sector.

Real-World Examples

In the realm of heavy industry, the practical application of Artificial Intelligence (AI) has yielded significant results, showcasing its potential to transform traditional processes and enhance operational efficiency. Two compelling case studies highlight the successful implementation of AI in heavy industry: predictive maintenance success and process optimization in manufacturing.

Case Study 1: Predictive Maintenance Success

Predictive maintenance, a key application of AI in heavy industry, has revolutionized how organizations approach equipment maintenance. By leveraging AI algorithms to analyze data from sensors and historical maintenance records, companies can predict when machinery is likely to fail and proactively schedule maintenance to prevent costly downtime.

| Metric | Traditional Maintenance | Predictive Maintenance with AI |

| Downtime | Unplanned downtime due to breakdowns | Reduced downtime through proactive maintenance |

| Cost | Higher maintenance costs due to emergency repairs | Lower maintenance costs with scheduled repairs |

| Efficiency | Reactive approach to maintenance | Proactive maintenance strategy |

Implementing predictive maintenance has enabled companies to transition from a reactive maintenance model to a proactive one, resulting in increased operational efficiency, reduced maintenance costs, and improved overall equipment reliability.

Case Study 2: Process Optimization in Manufacturing

AI's role in process optimization within the manufacturing sector has reshaped production processes by enhancing efficiency and quality control. By integrating AI-powered systems into manufacturing workflows, companies can analyze vast amounts of data in real-time, identify patterns, and make data-driven decisions to optimize production processes.

| Metric | Conventional Manufacturing | AI-Optimized Manufacturing |

| Production Yield | Variability in production output | Consistent and optimized production yield |

| Quality Control | Manual inspection processes | Automated quality control systems |

| Efficiency | Manual production planning | AI-driven production optimization |

The adoption of AI-driven process optimization has led to increased production yield, improved quality control, and enhanced operational efficiency in manufacturing facilities. By harnessing the power of AI, companies can streamline their manufacturing processes, reduce waste, and meet production targets with greater precision.

These real-world examples underscore the transformative impact of AI in heavy industry, showcasing its ability to drive innovation, improve operational processes, and pave the way for a more efficient and sustainable future in industrial settings.

Future Prospects

As heavy industry continues to evolve, the potential of artificial intelligence (AI) to revolutionize the sector is increasingly evident. The integration of AI technologies holds promise for transforming traditional practices and driving efficiency in industrial operations.

AI's Potential to Revolutionize Heavy Industry

AI's role in heavy industry is poised to revolutionize how operations are conducted and managed. By harnessing the power of AI algorithms and machine learning capabilities, businesses in the heavy industry sector can enhance productivity, optimize processes, and improve overall performance.

One of the key areas where AI is making a significant impact is in predictive maintenance. By leveraging AI-powered predictive analytics, companies can anticipate equipment failures before they occur, enabling proactive maintenance and reducing downtime. This predictive approach not only saves costs but also enhances operational efficiency by minimizing disruptions.

Moreover, AI can play a crucial role in process optimization within heavy industry settings. Through the analysis of vast amounts of data generated during production processes, AI algorithms can identify patterns, detect inefficiencies, and suggest optimization strategies. This data-driven approach enables companies to streamline operations, increase output, and achieve higher levels of productivity.

Continued Innovation and Development

Looking ahead, the trajectory of AI in heavy industry points towards continued innovation and development. As AI technologies mature and become more sophisticated, the capabilities they offer to the heavy industry sector will expand further. From advanced predictive analytics to autonomous systems, the future of AI in heavy industry holds immense potential for driving transformative change.

To ensure that AI continues to deliver value to heavy industry, ongoing innovation and development in AI applications are essential. Collaborations between industry experts, data scientists, and AI specialists will be crucial in pushing the boundaries of what is achievable with AI in heavy industry. By fostering a culture of innovation and embracing emerging AI technologies, businesses can stay at the forefront of the digital transformation wave sweeping through the heavy industry sector.

As heavy industry embraces AI's potential and commits to continued innovation and development, the sector is poised to undergo a significant transformation. By leveraging the power of AI technologies, businesses in heavy industry can unlock new opportunities, drive operational efficiencies, and pave the way for a more sustainable and productive future.

Unlocking AI's Potential for Heavy Industry

As we explore the potential of AI in transforming heavy industry, it's clear that adopting innovative technologies can drive efficiency and reduce operational costs. AI can optimize processes, enhance predictive maintenance, and improve decision-making, ultimately leading to significant productivity gains.

At LK Tech, a Cincinnati-based IT services company, we specialize in integrating advanced AI solutions tailored to meet the unique needs of heavy industries. Our team is dedicated to providing top-notch support, ensuring a seamless transition to smarter operations. Don’t miss out on the opportunity to revolutionize your business—contact us today to learn how we can help you harness the power of AI for a more efficient future.